Fuel assemblies in the core of nuclear reactors

The nuclear fuel assemblies, that vary from one reactor family to another, constitutes one of the main parameters involved in their design.

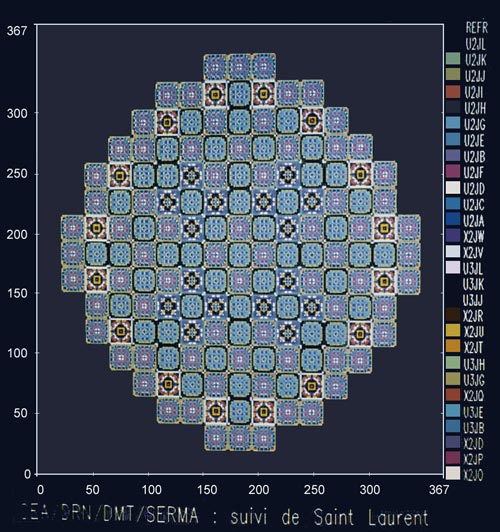

Layout of a reactor’s core

Layout of the core of a pressurized water reactor, made during studies of plutonium recycling. The diagram shows the MOX fuel assemblies containing plutonium (in blue) among the majority of those containing usual enriched uranium (UOX).

CEA

The materials present in the core of a classical reactor must fulfill three functions: produce energy, slow down neutrons to maintain the chain reaction and remove heat. Nuclear fuel, neutron moderator and heat transfer fluid are required.

A reactor component can perform several functions. In a pressurized water PWR reactor, it is the same liquid, water under pressure, which plays the role of moderator and evacuates the heat. In some research reactors, the uranium fuel is dissolved in molten salts (chlorides or fluorides) which also carry away heat. In fast neutron reactors, the moderator is not necessary.

Apart from the particular case of molten salt reactors, the fuel is in a solid state, in the form of insoluble oxides. As irradiation progresses, more and more radioactive products are generated, some of them gaseous or mobile. These elements must be confined, by coating them in a sheath which must be resistant to temperature and corrosion while being transparent to neutrons.

In a PWR reactor, the fuel rods are coated in zircaloy cladding, a zirconium and tin alloy. These rods are assembled into assemblies which are immersed in the high pressure water of the reactor vessel. The mosaic arrangement of the fuel is heterogeneous.

In these reactors, the most commons, fuel rods are generally composed of uranium oxide pellets – enriched with the U-235 fissile isotope – coated in a zircaloy sheath. In addition to this UOX fuel, the core of some PWR reactors include around 30% of assemblies made up of a mixture of uranium and plutonium oxide, called MOX (Mixed oxides).

The layout of boiling water reactors (BWR) is close to that of PWR reactors. That of heavy water and natural uranium reactors (CANDU) allows continuous unloading of fuel rods. In the RBMK reactors of the former Soviet Union, the coolant (water) and the moderator (graphite) are different.

An original arrangement will be that of high temperature reactors. The fuel would be placed in the center of small balls coated with a layer of silicon carbide, a very refractory material which resists temperatures up to 1600° C and ensures very good confinement of radioactive products. This confinement would be reinforced by a layer of porous carbon which surrounds the fuel core. These balls are cooled by helium under high pressure and blocks of graphite playing the role of moderator.

Next : PWR fuel assemblies

See also :

PWR reactors

BWR reactors

Molten salt reactors

In french : Réacteurs à hautes températures

Other articles on the subject « Nuclear Fuel »

Nuclear Fuel Cycle

The front-end and the back-end of the cycle… The nuclear fuel cycle includes all nuclear op[...]

Cycle Front End

From the extraction of uranium to the fuel fabrication The front-end of the nuclear cycle is the [...]

Isotopic Separation

The access key to the fuel of modern nuclear power plants … and to atomic weapons The uranium fue[...]

Ultracentrifugation

A separation process economical in energy, but proliferating The principle of centrifuges has lon[...]

Gaseous Diffusion

The first enrichment process, a large consumer of electricity The gaseous diffusion process was t[...]

PWR fuel assemblies

Fuel assemblies in the core of PWR Reactors The core of a pressurized water reactor (PWR) is cont[...]

Plutonium Use

A fissile element produced in nuclear reactors In February 1941 the American physicist Glenn Seab[...]

Pu : Fuel, bomb or Waste ?

Plutonium dark and bright sides … Sensitive material, like the roman god Janus, plutonium h[...]

MOX fuels

Introducing plutonium in nuclear fuels For energy production, plutonum is gold ! One gram of plut[...]

Thorium Fuels

Uranium 233: a fissile nucleus made from thorium Thorium is more abundant than uranium in the Ear[...]