The reactors of tomorrow before those of after tomorrow

Designed in the 1990s, third-generation reactors are expected to gradually replace the second-generation reactors currently in service.

France has chosen the EPR (European Pressurized water Reactor), of which a protype is being built on the Flamanville site. Due to multiple delays, its connection to the electricity grid, originally scheduled for 2012, is expected to take place in 2019. By early 2018, the Flamanville EPR was entering its final stage, with fuel loading expected for the fourth quarter of 2018. On the same date, the Chinese Nuclear Safety Authority was preparing to give the go-ahead for fuel loading in its first Taishan EPR, with a view to connecting to the grid by the summer of 2018.

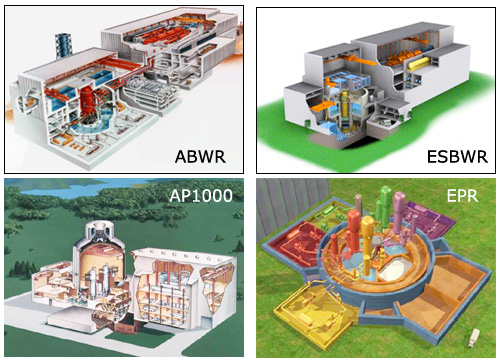

Models of third generation reactors

Some “evolutionary” models proposed by the main American-Japanese and European reactor manufacturers: For boiling water reactors ABWR (Advanced BWR) and ESBWR (Economic Simplified BWR) of General Electrics-Hitachi; For pressurized water reactors, the Westinghouse-Toshiba’s Advanced PWR (AP-1000) and AREVA’s European Evolutionnary PWR (EPR).

© DR

They are often very large reactors, whose power reaches 1600 MWe in the case of the EPR. The main players are competing for the future market: advanced pressurized water reactors with AREVA for the EPR and Westinghouse-Toshiba for the AP-1000; advanced boiling water reactors with ABWR and US-Japan ESBWR from General-Electric-Hitachi; or Russian reactors (VVER-1200) from Rosatom or Canadian heavy water CANDU (ACR-1000).

Among the 41 new plants under construction worldwide in June 2008, a few were of the Generation, such as the first EPRs in Olkiluoto in Finland and Flamanville in France, as well as Taishan in China in the province of Guangdong. At the same date, nine orders for such nuclear power units had been confirmed in China, Korea, Japan and Russia.

Construction of the first EPR in Finland

In 2009, the reactor dome at Olkiluoto was installed, the first EPR reactor to be built in Finland by AREVA, Siemens and the Finnish electrician TVO. The project has been delayed for several years, the commissioning of the plant being later scheduled for May 2019. The expected loss due to this delay is estimated at 3.9 billion euros. The construction site suffered from an ongoing procedure in which Areva and TVO claim damages of several billion euros each.

© Bouygues/Pierre-François Grosjean

A safety pushed to the maximum ……

Thus, although second generation light water reactors have an excellent record of safety, great efforts have been made to further improve this safety and reduce the already very low levels of radioactivity released into the environment.

EPR reactors have very advanced safety systems. A double thick concrete wall ensures the containment of radioactive materials in case of accidental fusion of the core. A hydrogen recombination system allows to avoid hydrogen accumulation and therefore detonation. The protection against earthquakes is improved. A significant novelty is a “corium recuperator”, a device that would reduce limit as much as possible the consequences of a core fusion that would occur, despite the multiple preventive measures. Safety is finally increased by the presence of more than redundant security and control systems.

This search for maximum security increases the cost. The high EPR cost is one of the reasons for the loss in 2010 of a multi-unit contract in the Gulf Emirates to the benefit of South Korean competitors. In addition, this powerful reactor is not adapted to the needs and desires of countries looking for less powerful units. For this reason, AREVA and Mitsubishi offer a “small EPR”, the ATMEA. In 2013, Turkey signed a contract for the construction of four ATMEAs on the Black Sea.

Chinese AP1000 reactors. Technology transfers.

China has started an ambitious program of installing nuclear power plants in the northern Jiangsu and Zhejiang coastal regions. These projects will be equipped with 6 sinized AP1000 reactors. The hydrostatic test of the primary circuit of unit 1 of the Sanmen power plant, the first series of AP1000 reactors, was successfully carried out on May 26, 2016.

© Westinghouse (Source RGN and Ambassade de France à Pékin).

Russia and China leaders for generation III reactors

Current leader for fast neutron reactors, Russia is also the first country to have commissioned two VVER-1200 generation III reactors, Novovoronej-6 in 2016 and Leningrad NPP in 2018. The VVER reactor sector is pressurized. Other reactors are under construction or project.

In contrast to Europe, China has started an ambitious nuclear program to meet its huge energy needs. This program foresees a 58 GW (Gigawatt) nuclear fleet of (the equivalent of the French fleet) in service in 2020 plus 30 GW under construction. During the period 2016-2020 of the Chinese Five-Year Plan, new nuclear power plants will be launched in coastal regions, with 6 new units of 1,000 MW every year on average.

The first EPR to come into service in 2018 will probably be those of Taishan in China. China is also expected to see the arrival of the first AP-1000s, whose construction began in 2009 in Haiyang (Shandong) and Sanmen (Zhejiang). Considered the most advanced Generation III reactor due to its passive safety systems, the Westinghouse-Toshiba’s AP1000 (Advanced PWR, 1100 MWe) is one of China’s prefered choices for its nuclear program.

Thanks to technology transfers, a large part of the components for the AP1000 reactor of the Sanmen and Haiyang sites (tank, steam generator, control rod mechanism, internal structure, popes of the primary circuit, pressurizer, steel containment enclosure …) was made up by Chinese manufacturers.

Sign of the times, China goes further, by offering to the market its own third-generation reactor, the Hualong … one of which may be built in England …

Other articles on the subject « Future Reactors »

EPR Reactors

EPR: a third generation pressurized water reactor Third generation reactors are reactors intended[...]

The nuclear option ?

Energy challenge : meeting energy demands of the Future The emergence of huge future needs by de[...]

Generation IV

Towards a fourth generation of reactors To meet the formidable challenges of sustainable developm[...]

Molten Salt Reactors

Promising reactors … but in a remote future Molten Salt Reactors are very different in desi[...]