The spent fuel reprocessing option

Spent fuel pool at La Hague

Spent fuel assemblies from French reactors are stored for three to five years in large pools at the La Hague plant until they can be reprocessed. Assemblies that are not destined for reprocessing are stored in other pools, often close to the reactors, until it is decided what to do with them. This is the case of spent fuel from American reactors.

© AREVA/ Taillat (Jean-Marie)

Spent fuel reprocessing is derived from a process called the PUREX process, which was initially developed to extract plutonium for military purposes. Used on an industrial scale, it is now used simply to separate uranium and plutonium . Once separated, uranium and plutonium are considered as recoverable materials. The highly radioactive residue is considered as real waste made up of

. Once separated, uranium and plutonium are considered as recoverable materials. The highly radioactive residue is considered as real waste made up of  fission products and minor actinides

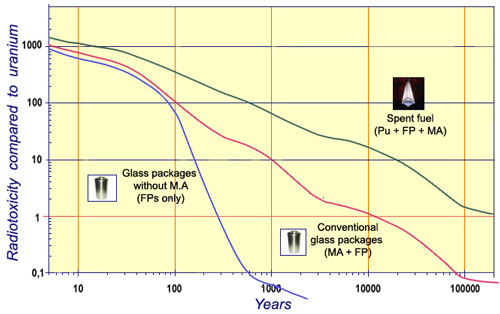

fission products and minor actinides . Extracting plutonium divides the volume and radiotoxicity of high-level waste by about ten. While this process can be used to recover plutonium and depleted uranium, and even recycled uranium after re-enrichment, if the plutonium in question is not intended for burning in a reactor, then it becomes the main waste product. In that case, much larger geological waste repositories will be needed than those required for fission products and minor actinides alone.

. Extracting plutonium divides the volume and radiotoxicity of high-level waste by about ten. While this process can be used to recover plutonium and depleted uranium, and even recycled uranium after re-enrichment, if the plutonium in question is not intended for burning in a reactor, then it becomes the main waste product. In that case, much larger geological waste repositories will be needed than those required for fission products and minor actinides alone.

Separating plutonium is only justified if the plutonium is to be reused. Besides, there would be little sense in extracting this highly radiotoxic element simply to dispose of it in a geological repository. Most of the plutonium produced by French reactors is currently used to make MOX, fuel, which is only a moderately effective way of consuming plutonium.

fuel, which is only a moderately effective way of consuming plutonium.

Slightly radioactive uranium makes up 95% of the mass of spent fuel. Separating it significantly reduces the volume of waste. The facilities eventually required for disposing of glass packages will be smaller and less expensive than if spent fuel is not reprocessed.

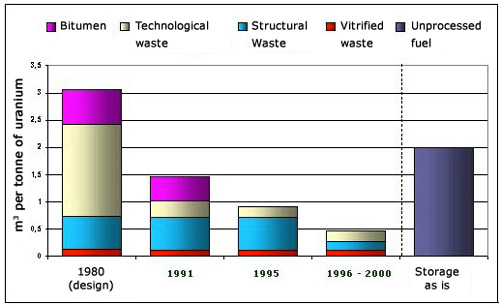

Reduction in waste volumes

Reprocessing at La Hague plant has divided waste volumes by six in 20 years. Waste now takes up four times less space than fuel left without reprocessing. While little change has been seen in the volume of the most radioactive fuel (HLW glass packages), that of technological waste from reprocessing operations and ILW-LL structural waste (hulls and end caps) has decreased considerably.

© AREVA (Source CNE – National Evaluation Commission)

The very high-level waste from reprocessing is vitrified, in other words immobilised in a glass matrix capable of trapping radioactivity for thousands of years. This glass material is highly resistant to radiation and chemical attack.

Fuel from civil reactors is currently reprocessed at two industrial facilities, La Hague in France and Sellafield in England. A third plant is currently being commissioned in Rokashomura, Japan. Other facilities exist in the nuclear defence sector. In France, weapons-grade materials are processed in a special facility at La Hague.

Reduction in waste radiotoxicity

One of the aims of waste management is to make waste less toxic before disposing of it. In this respect, vitrified waste after plutonium removal – the conventional glass packages – has a clear advantage over fuel disposed of as it is, without reprocessing. The advantage would be even greater if the actinides were removed from the glass packages. In this case, their radiotoxicity would drop to the level of the natural uranium from which they originated in “only” 300 years. That is not the case for existing glass packages.

© IN2P3 (Source CEA).

The road to advanced reprocessing Projects for what are known as Generation IV reactors are being investigated. Some of these reactors would be able to regenerate – or breed – their fuel and burn actinides as well as plutonium. Fuel reprocessing would become unavoidable with most Generation IV reactor concepts that would replace today’s slow (or thermal) reactors using uranium. Reprocessing in the future will be more advanced than the existing process and would also separate actinides and some long-lived fission products. It would then be possible to destroy these elements at specialised facilities or condition them in appropriate materials. There is no doubt that reprocessing is the key to clean nuclear power. The United States, which has long been clearly against or hesitant about reprocessing, is changing its view.

Other articles on the subject « The waste issue »

Waste or resource?

Spent fuel can still generate a lot of energy The fuel removed from a reactor core after three or[...]

Alternative to reprocessing

Leave fuel as it is : do not reprocess If the spent fuel does not undergo reprocessing, the fuel [...]

What to do with plutonium

A highly strategic material and a hazardous type of waste What becomes of plutonium is central to[...]

Plutonium options

Plutonium: hazardous waste or miraculous raw material? For those who advocate pulling out of nucl[...]

Costs comparison

Reprocessing or not reprocessing: a comparison Which option for dealing with spent fuel from reac[...]