Radioisotope production for nuclear medicine

Currently there are in Europe over 12 million medical procedures per year (diagnostic and therapy) using radioisotopes, i.e. more than 30,000 procedures per day. About 90% of radioisotopes are used for diagnostic purposes and 10% for therapies.

At the world scale, the number of people using nuclear medicine was estimated in 2016 to 35 million , either for a diagnosis or for a therapy. The demand for radioisotopes for these diagnoses and therapies was growing rapidly in both developed and fast-developing countries like China and India.

Radioisotopes production with a cyclotron

Invented in the early 1930s by the American physicist Ernest Lawrence, the cyclotron was the first particle accelerator. It is used today in large hospitals to locally produce radioactive very short lived tracers such as fluorine-18 used in Positron Emission Tomography in the screening and localization of cancerous cells.

© AFP et hôpital Saint-Louis

Radioisotopes are produced either with cyclotrons or with reactors. Cyclotrons may be installed on industrial sites or in large hospitals, which allows immediate use, The production, whose cost is high, is achieved by the shelling of a target by charged particles, usually protons.

Beta-plus emitters like fluorine-18 and short-lived radioelements (like thallium-201 for heart scintigraphies) are produced in cyclotrons and represent about 25% of radioisotopes used in diagnosis.

Fluorine 18, the tracer used in Positron Emission Tomography for cancer screening, is produced with a cyclotron. Water enriched with oxygen 18 is used (oxygen nucleus is close to – to a fluorine 18). Oxygen 18 nuclei are targeted with protons accelerated by the cyclotron; a nuclear reaction takes place, which converts oxygen into fluorine 18. After two or three hours of irradiation, the radioactive fluorine 18, is isolated and then attached to a radiophamaceutical glucose molecule.

Radioisotopes production

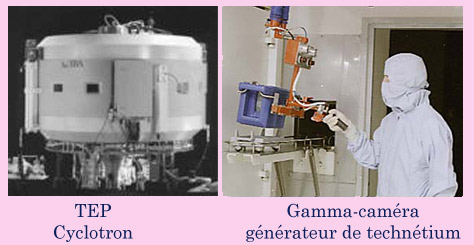

Positron Emission Tomography scans used very short lived radioisotopes. These isotopes should be produced by a cyclotron at the hospital itself or when the lifetime is enough long, delivered very quickly from a regional center (in the case of most used fluorine-18 the half-life is 110 minutes). The supply in technetium-99 for gamma cameras requires a much simpler device recharged twice a week : technetium-99 is needed in 70% of scintigraphies.

© IN2P3

Nuclear reactors allow the production of the majority of radioisotopes in greater quantities, at a lower cost. Neutrons trigger fissions in a target containing uranium-235. The radioisotopes produced should have a half-life long enough to enable their transport. Nuclear reactors ensure the production of many gamma emitters and all radionuclides used in therapy.

Molybdenum-99, the technetium-99 precursor

Currently, nearly 75% of scintigraphic examinations are made with technetium-99. The precursor of this radioisotope – molybdenum-99 – is produced through uranium-235 fissions in specialized reactors. About 6% of the uranium-235 fissions lead to molybdenum. The targets consist of small aluminum plate containing uranium enriched in uranium-235.

Until recently, this uranium was an Highly Enriched uranium (HEU), enriched to nearly 95% in isotope 235. Recent IAEA regulations imposed to replace this weapon-grade uranium with Low Enriched Uranium(LEU) enriched to 20% or less. The target date was the end of 2017.

The synthesis of radiopharmaceuticals products is also performed on the same site. The products are delivered by a licensed carrier to the various nuclear medicine services. Radiopharmaceuticals are essentially used in the form of injectable solutions or in the form of capsules (therapy by iodine-131 for example).

The production of technetium-99m is provided by a “technetium generator” and is delivered once or twice a week in each nuclear medicine department. The technetium-99m solution is obtained by elution of a chromatographic column of alumina on which molybdenum 99 (period 66 hours) is fixed .

Radiopharmaceuticals are prepared in a special room of nuclear medicine services (called “hot lab), The preparation and handling of pharmaceutical products are subject to strict radioprotection rules. Activities of tracers injected into the patient, are measured using a calibrated ionization chambers (activimeter). Radiaxtive products are confined within syringes fitted with sealed covers to minimize the irradiation of the medical staff.